1. Cov khoom siv brazing

(1) Titanium thiab nws lub hauv paus alloys tsis tshua muaj brazed nrog muag muag.Lub brazing muab tub lim siv rau brazing feem ntau suav nrog nyiaj puag, aluminium puag, titanium puag lossis titanium zirconium puag.

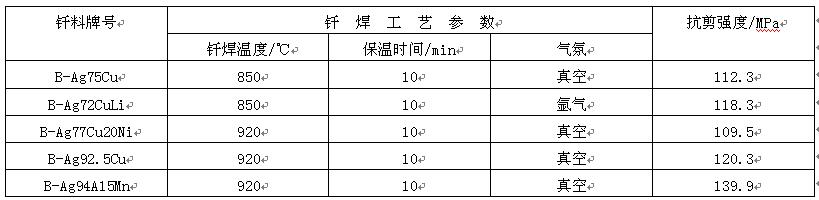

Silver-based solder feem ntau yog siv rau cov khoom siv nrog kev ua haujlwm kub tsawg dua 540 ℃.Cov pob qij txha siv cov nyiaj dawb huv solder muaj lub zog tsawg, yooj yim rau tawg, thiab tsis zoo corrosion kuj thiab oxidation kuj.Lub brazing kub ntawm Ag Cu solder yog qis dua li ntawm cov nyiaj, tab sis lub wettability txo nrog qhov nce ntawm Cu cov ntsiab lus.Lub Ag Cu solder uas muaj ib qho me me ntawm Li tuaj yeem txhim kho lub wettability thiab alloying degree ntawm cov solder thiab lub hauv paus hlau.AG Li solder muaj cov yam ntxwv ntawm qhov qis melting point thiab muaj zog reducibility.Nws yog tsim rau brazing titanium thiab titanium alloys hauv kev tiv thaiv huab cua.Txawm li cas los xij, lub tshuab nqus tsev brazing yuav ua rau lub cub tawg vim Li evaporation.Ag-5al- (0.5 ~ 1.0) Mn muab tub lim hlau yog cov nyiam muab tub lim hlau rau nyias-walled titanium alloy Cheebtsam.Lub brazed sib koom ua ke muaj oxidation zoo thiab corrosion kuj.Lub zog shear ntawm titanium thiab titanium alloy pob qij txha brazed nrog nyiaj puag muab tub lim hlau yog qhia hauv Table 12.

Table 12 brazing txheej txheem tsis thiab sib koom ua ke ntawm titanium thiab titanium alloys

Lub brazing kub ntawm txhuas raws li solder yog tsawg, uas yuav tsis ua rau qhov tshwm sim ntawm titanium alloy β Theem transformation txo qhov yuav tsum tau rau kev xaiv ntawm brazing fixture cov ntaub ntawv thiab cov qauv.Kev sib cuam tshuam ntawm cov hlau muab tub lim thiab lub hauv paus hlau yog qhov tsawg, thiab kev sib cais thiab kev sib cais tsis pom tseeb, tab sis cov yas ntawm cov hlau muab tub lim yog qhov zoo, thiab nws yog ib qho yooj yim rau yob cov muab tub lim hlau thiab lub hauv paus hlau ua ke, yog li nws yog heev haum rau brazing titanium alloy radiator, honeycomb qauv thiab laminate qauv.

titanium raws li los yog titanium zirconium raws li fluxes feem ntau muaj Cu, Ni thiab lwm yam ntsiab lus, uas yuav sai sai diffuse mus rau hauv lub matrix thiab react nrog titanium thaum lub sij hawm brazing, ua rau matrix corrosion thiab tsim ntawm nkig txheej.Yog li ntawd, lub brazing kub thiab tuav lub sij hawm yuav tsum nruj me ntsis tswj thaum lub sij hawm brazing, thiab yuav tsum tsis txhob siv rau brazing ntawm nyias-walled lug kom deb li deb li sai tau.B-ti48zr48be yog ib yam Ti Zr solder.Nws muaj qhov zoo wettability rau titanium, thiab lub hauv paus hlau tsis muaj kev nyiam ntawm cov nplej loj hlob thaum lub sij hawm brazing.

(2) Brazing muab tub lim hlau rau zirconium thiab lub hauv paus alloys brazing ntawm zirconium thiab lub hauv paus alloys feem ntau suav nrog b-zr50ag50, b-zr76sn24, b-zr95be5, thiab lwm yam., uas yog siv dav hauv brazing ntawm zirconium alloy kav ntawm nuclear fais fab reactors.

(3) Lub brazing flux thiab tiv thaiv huab cua titanium, zirconium thiab puag alloys tuaj yeem tau txais txiaj ntsig zoo hauv lub tshuab nqus tsev thiab inert cua (helium thiab argon).High purity argon yuav tsum tau siv rau argon shielded brazing, thiab cov lwg taw tes yuav tsum yog -54 ℃ los yog qis dua.Cov flux tshwj xeeb uas muaj fluoride thiab chloride ntawm cov hlau Na, K thiab Li yuav tsum tau siv rau cov nplaim taws.

2. Brazing tshuab

Ua ntej brazing, saum npoo yuav tsum tau ntxuav kom huv si, degreased thiab oxide zaj duab xis tshem tawm.Thick oxide zaj duab xis yuav tsum raug tshem tawm los ntawm kev siv tshuab, txoj kev xuab zeb blasting los yog molten ntsev da dej.Cov yeeb yaj kiab oxide nyias tuaj yeem raug tshem tawm hauv cov tshuaj uas muaj 20% ~ 40% nitric acid thiab 2% hydrofluoric acid.

Ti, Zr thiab lawv cov alloys tsis raug tso cai rau kev sib cuag ntawm qhov sib koom ua ke nrog huab cua thaum lub sij hawm brazing cua sov.Brazing tuaj yeem ua tau raws li kev tiv thaiv ntawm lub tshuab nqus tsev lossis roj inert.High zaus induction cua sov lossis cua sov hauv kev tiv thaiv tuaj yeem siv tau.Induction cua sov yog txoj kev zoo tshaj plaws rau me me symmetrical qhov chaw, thaum brazing hauv qhov cub yog qhov zoo dua rau cov khoom loj thiab nyuaj.

Ni Cr, W, Mo, Ta thiab lwm yam ntaub ntawv yuav tsum raug xaiv raws li cov khoom cua sov rau brazing Ti, Zr thiab lawv cov alloys.Cov cuab yeej siv nrog cov graphite raug raws li cov khoom cua sov yuav tsum tsis txhob siv kom tsis txhob muaj cov pa phem.Brazing fixture yuav tsum tau ua los ntawm cov ntaub ntawv uas muaj qhov kub thiab txias zog, zoo xws li thermal expansion coefficient rau Ti los yog Zr, thiab tsawg reactivity nrog lub hauv paus hlau.

Post lub sij hawm: Jun-13-2022