1. brazeability

Cov cuab yeej brazing ntawm txhuas thiab aluminium alloys yog neeg pluag, feem ntau vim yog cov yeeb yaj kiab oxide ntawm cov npoo yog qhov nyuaj rau tshem tawm.Aluminium muaj affinity zoo rau oxygen.Nws yog ib qho yooj yim los tsim ib tug ntom, ruaj khov thiab siab melting point oxide zaj duab xis Al2O3 ntawm qhov chaw.Nyob rau tib lub sijhawm, aluminium alloys muaj cov magnesium tseem yuav ua rau cov yeeb yaj kiab ruaj khov oxide heev.Lawv yuav xav hnyav npaum li cas lub plhaw thiab nthuav tawm.Thiab nyuaj rau tshem tawm.Thaum brazing, tus txheej txheem brazing tuaj yeem nqa tawm tsuas yog nrog flux kom zoo.

Thib ob, kev ua haujlwm ntawm txhuas thiab aluminium alloy brazing yog qhov nyuaj.Lub ntsiab lus melting ntawm txhuas thiab txhuas alloy tsis yog ntau txawv ntawm qhov ntawm brazing muab tub lim hlau siv.Qhov kev xaiv tau kub kub ntau yam rau Brazing yog qhov nqaim heev.Kev tswj qhov kub me me yog qhov yooj yim los ua rau overheating overheating lossis txawm melting ntawm lub hauv paus hlau, ua rau cov txheej txheem brazing nyuaj.Qee cov alloys alloys muaj zog los ntawm kev kho cua sov yuav tseem yuav ua rau cov khoom siv cua sov kuj tseem yuav txo cov khoom cua sov los yog cov khoom siv ntawm cov pob qij txha.Thaum lub sij hawm nplaim taws los, nws yog qhov nyuaj rau kev txiav txim rau cov xim txhuas tsis hloov thaum cua sov, uas tseem yuav tsum muaj rau cov neeg teb xov tooj theem.

Ntxiv mus, kev xeb tsis kam ntawm txhuas thiab aluminium alloy brazed pob qij txha yog yooj yim cuam tshuam los ntawm cov chaw ua tub lim thiab fluxes.Lub peev xwm electrode ntawm txhuas thiab txhuas alloy yog txawv ntawm cov ham, uas txo cov xeb uas muaj kev sib koom ua ke, tshwj xeeb tshaj yog rau cov mos mos sib koom ua ke.Tsis tas li ntawd, feem ntau cov fluxes siv nyob rau hauv brazing ntawm txhuas thiab aluminium alloys muaj kev sib kho corrosivity.Txawm hais tias lawv tau raug ntxuav tom qab brazing tom qab brazing, cov cawv ntawm fluxes ntawm corrosion tsis kam ntawm cov pob qij txha yuav tsis raug tshem tawm tag nrho.

2. brazing khoom

(1) branzing ntawm txhuas thiab aluminium alloys yog qhov tsis tshua muaj siv cov tub lim hlau thiab cov hlau hluav taws xob sib txawv heev, uas yog qhov yooj yim los ua rau hluav taws xob ntawm kev sib koom tes.Cov mos mos soldering tsuas yog adinc raws li solder thiab tin lead cam (150 ~ jour) thiab cua kub sing (370 ~ 430 ℃) raws li cov ntau yam.Thaum Tin Lead Solder siv thiab tooj liab lossis npib tsib yog ua ntej rau Brazing, yog li txhawm rau txhim kho lub xeb tsis kam ua ke.

Brazing ntawm txhuas thiab aluminium alloys tau siv dav, xws li cov lus qhia lim, Evapator, Radiator thiab lwm yam.Tsuas yog txhuas raws li cov hlau tuaj yeem siv tau rau brazing ntawm txhuas thiab aluminium alloys, ntawm Aluminium silicon chaw ua haujlwm me me yog qhov feem ntau dav siv.Cov lus qhia tshwj xeeb ntawm daim ntawv thov thiab lub zog shear ntawm cov pob qij txha ntaus tau muaj nyob hauv Table 8 thiab Rooj 9 feem.Txawm li cas los xij, lub ntsiab lus melting ntawm cov hamding no yog ze rau ntawm lub hauv paus hlau, yog li cov cua sov tswj thiab raug tshuaj kom nruj thiab txawm melting ntawm lub hauv paus hlau.

Rooj 8 daim ntawv thov tau txais ntawm Brazing cov tub lim cov hlau rau txhuas thiab aluminium alloys

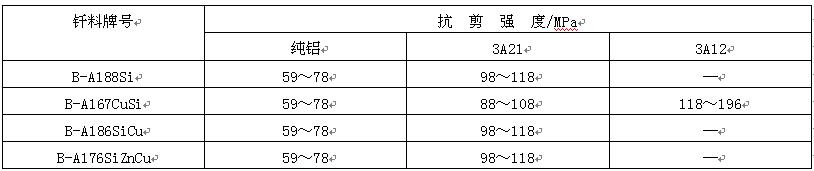

Cov Lus 9 Shear Lub Zog ntawm Aluminium thiab Aluminium Alloy Cov Koom Tes Ua Ke Nrog Aluminium Silicon Sher Cov Hlau

Aluminium silicon soler feem ntau yog muab rau ntawm cov hmoov, muab tshuaj txhuam, hlau lossis ntawv.Hauv qee kis, cam cov paib sib xyaw nrog txhuas raws li txhuas raws li tus tub ntxhais thiab txhuas silicon solder li cov cladding yog siv.Qhov no hom solder sib xyaw phaj yog tsim los ntawm cov qauv hydraulic thiab feem ntau siv los ua ib feem ntawm cov khoom lag luam brazing.Thaum brazing, cov tub rog brazing ua ke ntawm cov phaj sib dhos thiab hnav tso rau hauv kev ua ntawm capillary thiab nqus kom sau qhov sib txawv ntawm kev sib tshuam.

(2) flux thiab kev thaiv cov roj rau txhuas thiab txhuas alloy brazing, tshwj xeeb flux feem ntau siv los tshem tawm zaj duab xis.Cov organic flux raws li triethanine, xws li FS204, yog siv nrog tsawg-kub mos mos.Qhov zoo ntawm flux no yog tias nws muaj me me corrosion nyhuv rau lub hauv paus hlau, tab sis nws yuav cuam tshuam ntau npaum li roj, uas yuav cuam tshuam rau kev ntub dej thiab caulking ntawm kev sib tsoo.Cov tshuaj flux raws li zinc chloride, xws li FS203 thiab FS220A, yog siv nrog nruab nrab kub thiab kub muag muag.Cov tshuaj tiv thaiv flux yog corrosive heev, thiab nws cov seem yuav tsum tau muab tshem tawm tom qab no.

Tam sim no, lub brazing ntawm txhuas thiab aluminium alloys tseem muaj kev sib raug zoo los ntawm Flux tshem tawm.Tus brazing flux siv suav nrog chloride boed flux thiab fluoride raws li flux.Chloride boed flux muaj lub peev xwm tshem tawm oxide zaj duab xis thiab zoo fluidity, tab sis nws muaj kev cuam tshuam zoo ntawm cov hlau.Nws cov seem yuav tsum raug tshem tawm tag nrho tom qab brazing.Fluoride boil boed flux yog hom tshiab ntawm flux, uas muaj cov yeeb yaj kiab tshem tawm zoo thiab tsis muaj xeb rau cov hlau.Txawm li cas los xij, nws tau muaj lub ntsiab muag siab thiab tsis zoo thermal stability, thiab tsuas yog siv nrog txhuas silicon solder.

Thaum brazing txhuas thiab txhuas alloys, lub tshuab nqus tsev, nruab nrab lossis cov inert cua feem ntau siv.Thaum lub tshuab nqus brazing yog siv, lub tshuab nqus tsev yuav tsum feem ntau mus txog qhov kev txiav txim ntawm 10-3pa.Thaum nitrogen lossis argon roj yog siv rau kev tiv thaiv, nws txoj kev huv yuav tsum muaj siab heev, thiab lub lwg yuav tsum qis dua -40 ℃

3. Brazing technology

Brazing ntawm txhuas thiab aluminium alloys muaj siab yuav tsum tau ua rau kev ntxuav cov workpiece nto.Txhawm rau kom tau txais cov khoom zoo, cov roj stain thiab oxide zaj duab xis nyob rau saum npoo yuav tsum tau muab tshem tawm ua ntej brazing.Tshem cov roj stain ntawm saum npoo nrog NA2COY aqueousous daws ntawm qhov kub ntawm 60 ~ 70 ℃ rau 5 ~ 10min, thiab tom qab ntawd yaug nrog dej huv;Cov zaj duab xis oxide tawm tuaj yeem raug tshem tawm los ntawm Naoh aqueous daws nyob rau qhov kub ntawm 20 ~ 4min, thiab tom qab ntawd thiab tom qab ntawd ntxuav nrog dej kub;Tom qab tshem cov roj stain thiab oxide zaj duab xis nyob rau saum npoo, lub workpient yuav raug kho nrog Gloss rau 2 ~ 5min, ces ntxuav hauv dej ntws thiab thaum kawg ziab.Txoj kev ua haujlwm kho los ntawm cov qauv no yuav tsis tau kov los yog kis nrog lwm cov av, thiab yuav tsum raug ntsia hauv 6 ~ 8h.Nws yog qhov zoo dua rau bark tam sim ntawd yog tias ua tau.

Cov txheej txheem brazing ntawm txhuas thiab aluminium alloys tsuas yog muaj cov nplaim taws, soldering hlau brazing thiab cua sov branzing.Cov hau kev feem ntau siv flux hauv brazing, thiab muaj qhov yuav tsum ua kom nruj ntawm qhov kub kub thiab tuav lub sijhawm.Thaum lub sij hawm nplaim taws thiab soldering hlau brazing, zam cua sov tus flux ncaj qha los tiv thaiv cov flux los ntawm kev kub ntxhov thiab tsis ua tiav.Vim tias txhuas tuaj yeem ua tau los ntawm cov mos mos nrog cov ntsiab lus zinc high highMuaj qee kis, lub brazing ntawm txhuas thiab aluminium alloys qee zaum tsis siv flux, tab sis siv ultrasonic lossis scraping txoj kev kom tshem tawm cov yeeb yaj kiab.Thaum siv scraping kom tshem tawm cov yeeb yaj kiab rau brazing, ua ntej tshav kub ua kom sov, thiab tom qab ntawd txhuam lub pas dej ua ke nrog kev ua haujlwm (los yog scraping cuab yeej).Thaum rhuav tshem cov yeeb yaj kiab Oxide Oxide, qhov kawg ntawm kev sib tsoo yuav yaj thiab ntub lub hauv paus hlau.

Brazing txoj kev ntawm txhuas thiab aluminium alloys tsuas yog suav nrog cov nplaim taws, rauv taws, dip brazing thiab roj thaiv cov paib brazing.Nplaim ci brazing yog feem ntau siv rau kev ua haujlwm me me thiab ib leeg ntau lawm.Txhawm rau zam qhov tsis ua tiav ntawm flux vim tias qhov kev sib tiv tauj cua nplaim taws thiab cov flux thaum siv cov roj oxyacetylene nrog kev tiv thaiv kev tiv thaiv kab mob oxidation.Thaum lub sij hawm tshwj xeeb brazing, tus brazing flux thiab cov muab tub lim rau ntawm qhov chaw brazed ua ntej thiab ua kom sov tib lub sijhawm nrog kev ua haujlwm;Lub workpiece kuj tseem tuaj yeem ua kom sov rau lub tshuab tawg ua ntej, thiab tom qab ntawd cov yas zais nrog flux tuaj yeem xa mus rau qhov chaw ua haujlwm;Tom qab flux thiab muab tub lim hlau yog melted hlau yog meled, cov nplaim cua kub yuav raug muab tshem tawm qeeb tom qab tus muab tub lim hlau yog tusyees puv.

Thaum brazing txhuas thiab txhuas alloy nyob rau hauv ib lub cua cua sov, tus neeg muab tub lim rau hauv cov dej ua ntej los npaj cov tshuaj tuab nrog kev sib haum xeeb ntawm 50%, thiab tom qab ntawd coated lub caj dab caj dab.Tus nqi tsim nyog ntawm hmoov brazing flux kuj tseem tuaj yeem them rau ntawm cov neeg siv khoom siv hlau nplaum, thiab tom qab ntawd cov rooj sib sau ua ke yuav muab tso rau hauv cov cub hluavtaws rau cua sov.Txhawm rau tiv thaiv cov hlau hauv paus los ntawm overheating lossis txawm melting, lub cua sov yuav tsum tau nruj me ntsis.

Paste lossis ntawv ci solder feem ntau yog siv rau dip brazing ntawm txhuas thiab aluminium alloys.Lub rooj sib tham ua haujlwm yuav tsum yog ua ntej pib ua ntej pib ua kom nws qhov kub thiab txias kom tiv thaiv qhov kub thiab txias, thiab thim tawm hauv brazing flux rau brazing.Thaum brazing, lub sij hawm kub thiab tsheb kauj vab yuav tsum tau tswj hwm nruj.Yog tias qhov ntsuas kub siab dhau lawm, cov hlau hauv paus yog ib qho yooj yim kom yaj thiab ham yog yooj yim yuav ploj;Yog tias qhov ntsuas kub tsawg dhau, tus ham tsis tau yaj txaus, thiab tus nqi brazing txo qis.Lub tshuab ntsuas kub tau txiav txim siab raws li hom thiab qhov loj ntawm lub hauv paus, thiab feem ntau yog nruab nrab ntawm cov lim dej kub thiab cov khoom kub ntawm cov hlau hauv paus.Lub sijhawm ntsw ntawm lub tsev da dej yuav tsum xyuas kom meej tias cov ham tuaj yeem yaj thiab ntws los, thiab kev txhawb nqa yuav tsum tsis ntev.Txwv tsis pub, cov Silicon keeb hauv cov solder yuav diffuse mus rau hauv paus hlau, ua kom cov hlau nyob ze ntawm tus leeg nkig.

Hauv lub tshuab nqus ntshav ntawm txhuas thiab txhuas alloys, hlau ua hauj lwm cov kev ua haujlwm tau siv los hloov cov xim oxide ntawm txhuas thiab paub meej tias ntub thiab kev sib kis.Magnesium tuaj yeem siv ncaj qha rau ntawm cov qauv ua haujlwm hauv daim ntawv ntawm cov chav, lossis cov hlau nplaum tuaj yeem txuas ntxiv rau cov kab hlau tshuab sixia li ib qho alloy.Rau lub workpiece nrog cov qauv nyuaj, txhawm rau kom muaj cov txiaj ntsig tag nrho ntawm cov hlau ua kom zoo, uas yog, tus neeg ua haujlwm yog thawj zaug tso rau hauv lub thawv hlau stainless (feem ntau Lub npe hu ua lub npov txheej txheem), thiab tom qab ntawd muab tso rau hauv lub tshuab nqus tsev cua sov rau cua sov brazing.Lub tshuab nqus tsev txhuas thiab txhuas cov pob qij txha muaj pob qij txha du thiab tuab cov pob qij txha, thiab tsis tas yuav ntxuav kom huv si tom qab kev txhom mus;Txawm li cas los xij, lub tshuab nqus cov khoom siv tau kim, thiab cov tshuaj khib nyiab pov tseg lub cub tawg, yog li nws yuav tsum tau ntxuav thiab khaws cia ntau zaus.

Thaum brazing txhuas thiab txhuas alloys nyob rau hauv nruab nrab lossis inertium activator lossis flux tuaj yeem siv los tshem tawm zaj duab xis.Thaum magnesium activator yog siv los tshem tawm cov yeeb yaj kiab, tus nqi ntawm cov magnesium yuav tsum tau qis dua li ntawm lub tshuab nqus tsev.Feem ntau, w (mg) yog li 0.2% ~ 0.5%.Thaum cov ntsiab lus ntawm magnesium yog qhov siab, qhov zoo ntawm kev sib koom ua ke yuav raug txo kom tsawg.Nocolok Brazing txoj kev siv fluoride flux thiab nitrogen tiv thaiv yog txoj kev tshiab tau tsim sai sai nyob rau hauv xyoo tas los no.Txij li thaum cov lus pom zoo ntawm fluoride flux tsis nqus noo noo thiab tsis yog kev xeb kom aluminium, cov txheej txheem tshem tawm cov khoom seem flux tom qab Brazing tuaj yeem raug rho tawm.Nyob rau hauv kev tiv thaiv ntawm nitrogen, tsuas yog ib qho me me ntawm fluoride flux xav tau kom zoo ntub cov hlau, thiab nws yooj yim kom tau txais cov pob qij txha zoo.Ntawm tam sim no, no Nocolok Brazing txoj kev tau siv nyob rau hauv cov pawg ntau lawm ntawm aluminium radeator thiab lwm yam.

Rau txhuas thiab aluminium alloy brazed nrog flux tsis zoo li fluoride flux, flux residue yuav tsum tau muab tso tawm tag nrho tom qab kev txhom.Cov seem ntawm cov organic brazing flux rau txhuas tuaj yeem ntxuav nrog cov ineanol thiab trichloreth aquely queous daws, thiab thaum kawg ntxuav nrog kub thiab dej txias.Chloride yog qhov seem ntawm brazing flux rau txhuas, uas tuaj yeem muab tshem tawm raws li cov hauv qab no;Ua ntej, soak hauv dej kub ntawm 60 ~ 80 ℃ 10 feeb huv si cov seem ntawm kev sib koom tes nrog txhuam hniav, thiab ntxuav nws nrog dej txias;Tom qab ntawd soak nws nyob rau hauv 15% nitric acid aqueous daws rau 30min, thiab thaum kawg yaug nws nrog dej txias.

Post lub sij hawm: Jun-13-2022