1. Cov khoom siv brazing

(1)Brazing ntawm carbon steel thiab low alloy steel muaj xws li mos brazing thiab hard brazing. Cov khoom siv dav siv hauv cov khoom muag muag yog tin lead solder. Lub wettability ntawm no solder rau steel nce nrog nce ntawm tin cov ntsiab lus, yog li ntawd lub solder nrog siab tin ntsiab lus yuav tsum tau siv rau sealing pob qij txha. Fesn2 intermetallic compound txheej yuav tsim nyob rau ntawm qhov sib txuas ntawm tin thiab hlau hauv tin lead solder. Txhawm rau kom tsis txhob muaj qhov sib xyaw ua ke hauv cov txheej txheem no, lub brazing kub thiab tuav lub sijhawm yuav tsum tau tswj kom zoo. Lub zog shear ntawm carbon steel pob qij txha brazed nrog ob peb raug tin lead solders yog qhia nyob rau hauv Table 1. Ntawm lawv, lub zog sib koom tes brazed nrog 50% w (SN) yog qhov siab tshaj plaws, thiab lub zog sib koom ua ke nrog antimony dawb solder yog siab dua nrog antimony.

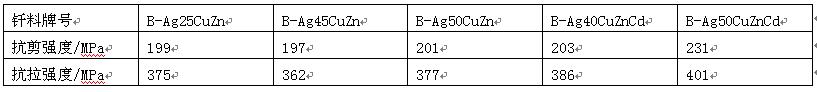

Table 1 shear zog ntawm carbon steel pob qij txha brazed nrog tin lead solder

Thaum brazing carbon steel thiab cov hlau tsis tshua muaj hlau, tooj liab ntshiab, tooj liab zinc thiab nyiaj tooj liab zinc brazing muab tub lim hlau yog siv ntau. Ntshiab tooj liab muaj lub siab melting point thiab yooj yim rau oxidize lub hauv paus hlau thaum lub sij hawm brazing. Nws yog tsuas yog siv rau gas shielded brazing thiab nqus brazing. Txawm li cas los xij, nws yuav tsum tau muab sau tseg tias qhov sib txawv ntawm cov pob qij txha yuav tsum tsawg dua 0.05mm kom tsis txhob muaj teeb meem uas qhov sib koom ua ke tsis tuaj yeem ua tiav vim qhov zoo ntawm cov tooj liab. Cov pa roj carbon steel thiab cov hlau tsis tshua muaj hlau sib koom ua ke nrog cov tooj liab ntshiab muaj zog. Feem ntau, lub zog shear yog 150 ~ 215mpa, thaum lub zog tensile faib ntawm 170 ~ 340mpa.

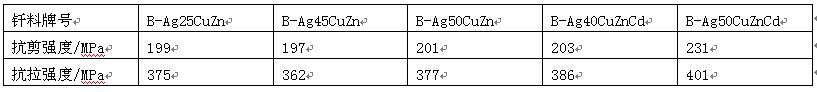

Piv nrog cov tooj liab ntshiab, lub melting point ntawm tooj liab zinc solder txo vim qhov sib ntxiv ntawm Zn. Txhawm rau tiv thaiv Zn evaporation thaum lub sij hawm brazing, ntawm ib sab, ib qho me me ntawm Si tuaj yeem ntxiv rau tooj liab zinc solder; Ntawm qhov tod tes, cov txheej txheem cua kub ceev yuav tsum tau siv, xws li nplaim taws brazing, induction brazing thiab dip brazing. Cov pob qij txha ntawm cov pa roj carbon steel thiab cov hlau tsis tshua muaj hlau brazed nrog tooj liab zinc muab tub lim hlau muaj lub zog zoo thiab plasticity. Piv txwv li, lub zog tensile thiab shear zog ntawm carbon steel pob qij txha brazed nrog b-cu62zn solder ncav cuag 420MPa thiab 290mpa. Lub melting point ntawm nyiaj tooj liab chaw nres tsheb solder yog qis dua li ntawm tooj liab zinc solder, uas yog yooj yim rau koob welding. Cov hlau muab tub lim no yog tsim rau cov nplaim hluav taws kub hnyiab, induction brazing thiab lub cub tawg brazing ntawm cov hlau thiab cov hlau tsis tshua muaj hlau, tab sis cov ntsiab lus ntawm Zn yuav tsum raug txo kom ntau li ntau tau thaum lub cub tawg, thiab cov cua kub yuav tsum tau nce. Brazing carbon steel thiab qis alloy steel nrog nyiaj tooj liab zinc muab tub lim tuaj yeem tau txais cov pob qij txha nrog lub zog zoo thiab cov yas. Cov ntaub ntawv tshwj xeeb tau teev nyob rau hauv Table 2.

Table 2 lub zog ntawm cov hlau tsis tshua muaj cov pob qij txha brazed nrog nyiaj tooj liab zinc solder

(2) Flux: flux lossis shielding gas yuav tsum tau siv rau brazing carbon steel thiab tsawg alloy steel. Qhov flux feem ntau yog txiav txim siab los ntawm kev xaiv cov khoom siv hlau thiab txoj kev brazing. Thaum siv cov tin lead solder, cov kua sib xyaw ntawm zinc chloride thiab ammonium chloride tuaj yeem siv ua flux lossis lwm yam tshwj xeeb flux. Cov seem ntawm cov flux no feem ntau yog corrosive heev, thiab qhov sib koom ua ke yuav tsum tau muab ntxuav kom nruj tom qab brazing.

Thaum brazing nrog tooj liab zinc muab tub lim hlau, fb301 lossis fb302 flux yuav tsum raug xaiv, uas yog, borax lossis sib xyaw ntawm borax thiab boric acid; Hauv cov nplaim hluav taws kub hnyiab, qhov sib xyaw ntawm methyl borate thiab formic acid kuj tseem tuaj yeem siv los ua brazing flux, uas B2O3 vapor plays lub luag haujlwm ntawm kev tshem tawm zaj duab xis.

Thaum siv nyiaj tooj liab zinc brazing muab tub lim hlau, fb102, fb103 thiab fb104 brazing fluxes tuaj yeem xaiv, uas yog, sib xyaw ntawm borax, boric acid thiab qee cov fluorides. Cov seem ntawm cov flux no yog corrosive rau ib qho twg thiab yuav tsum tau muab tshem tawm tom qab brazing.

2. Brazing tshuab

Qhov saum npoo yuav tsum tau welded yuav tsum tau ntxuav los ntawm txhua yam los yog tshuaj txoj kev los xyuas kom meej tias cov oxide zaj duab xis thiab cov organic teeb meem raug tshem tawm tag nrho. Qhov chaw ntxuav yuav tsum tsis txhob ntxhib heev thiab yuav tsum tsis txhob ua raws li cov hlau chips lossis lwm yam av.

Cov pa roj carbon steel thiab cov hlau tsis tshua muaj hlau tuaj yeem ua tau los ntawm ntau txoj hauv kev brazing. Thaum nplaim taws brazing, nruab nrab lossis me ntsis txo cov nplaim taws yuav tsum tau siv. Thaum lub sijhawm ua haujlwm, cov cua sov ncaj qha ntawm cov hlau muab tub lim thiab cov nplaim hluav taws yuav tsum zam kom ntau li ntau tau. Cov cua kub ceev xws li induction brazing thiab dip brazing yog qhov tsim nyog rau brazing ntawm quenched thiab tempered steel. Nyob rau tib lub sijhawm, quenching lossis brazing ntawm qhov kub qis dua tempering yuav tsum raug xaiv los tiv thaiv softening ntawm lub hauv paus hlau. Thaum brazing low alloy siab zog steel nyob rau hauv kev tiv thaiv huab cua, tsis tsuas yog siab purity ntawm cov pa yuav tsum tau, tab sis kuj gas flux yuav tsum tau siv los xyuas kom meej lub wetting thiab kis ntawm muab tub lim hlau rau saum npoo ntawm lub hauv paus hlau.

Cov dej ntws seem tuaj yeem raug tshem tawm los ntawm kev siv tshuaj lom neeg lossis kev siv tshuab. Cov residue ntawm cov organic brazing flux tuaj yeem ntxuav lossis ntxuav nrog roj av, cawv, acetone thiab lwm cov kuab tshuaj organic; Cov residues uas muaj zog corrosive flux xws li zinc chloride thiab ammonium chloride yuav tsum neutralized nyob rau hauv NaOH aqueous tov ua ntej, thiab ces ntxuav nrog dej kub thiab txias; boric acid thiab boric acid flux residues yog qhov nyuaj rau tshem tawm, thiab tsuas yog daws tau los ntawm kev siv tshuab lossis kev tso dej ntev ntev hauv dej.

Post lub sij hawm: Jun-13-2022