1. Brazeability

Nws yog ib qho nyuaj rau braze ceramic thiab ceramic, ceramic thiab hlau Cheebtsam. Feem ntau ntawm cov solder tsim ib lub pob ntawm cov ceramic nto, nrog me me los yog tsis ntub dej. Lub brazing muab tub lim hlau uas tuaj yeem ntub cov ceramics yog ib qho yooj yim los tsim ntau yam khoom sib txuas (xws li carbides, silicides thiab ternary lossis multivariate compounds) ntawm qhov sib koom ua ke thaum lub sij hawm brazing. Lub hav zoov ntawm cov tebchaw no cuam tshuam rau cov khoom siv kho tshuab ntawm kev sib koom ua ke. Tsis tas li ntawd, vim qhov sib txawv loj ntawm thermal expansion coefficients ntawm ceramic, hlau thiab solder, yuav muaj kev ntxhov siab nyob rau hauv kev sib koom ua ke tom qab lub brazing kub yog txias rau chav tsev kub, uas yuav ua rau kev sib koom ua ke.

Lub wettability ntawm solder ntawm lub ceramic nto tuaj yeem txhim kho los ntawm kev ntxiv cov khoom siv hlau rau cov khoom siv sib xws; Tsawg kub thiab lub sij hawm luv luv brazing tuaj yeem txo cov nyhuv ntawm cov tshuaj tiv thaiv interface; Lub thermal stress ntawm qhov sib koom ua ke tuaj yeem raug txo los ntawm kev tsim ib daim ntawv sib koom ua ke thiab siv ib leeg lossis ntau txheej hlau ua cov txheej txheem nruab nrab.

2. Solder

Ceramic thiab hlau feem ntau txuas nrog hauv lub tshuab nqus tsev lossis hydrogen thiab argon rauv. Ntxiv rau cov yam ntxwv dav dav, brazing muab tub lim hlau rau lub tshuab nqus tsev hluav taws xob yuav tsum muaj qee qhov tshwj xeeb. Piv txwv li, lub solder yuav tsum tsis txhob muaj cov ntsiab lus uas ua rau siab vapor siab, thiaj li tsis ua rau dielectric to thiab cathode lom ntawm cov cuab yeej. Nws feem ntau tau teev tseg tias thaum lub cuab yeej ua haujlwm, lub vapor siab ntawm lub solder yuav tsum tsis pub tshaj 10-3pa, thiab lub siab vapor siab impurities muaj yuav tsum tsis pub tshaj 0.002% ~ 0.005%; Lub w (o) ntawm lub solder yuav tsum tsis pub tshaj 0.001%, yog li kom tsis txhob muaj dej vapor generated thaum lub sij hawm brazing nyob rau hauv hydrogen, uas yuav ua rau splashing ntawm molten solder hlau; Tsis tas li ntawd, lub solder yuav tsum huv si thiab tsis muaj oxides saum npoo.

Thaum brazing tom qab ceramic metallization, tooj liab, puag, nyiaj tooj liab, kub tooj liab thiab lwm yam hlau alloy brazing muab tub lim yuav siv tau.

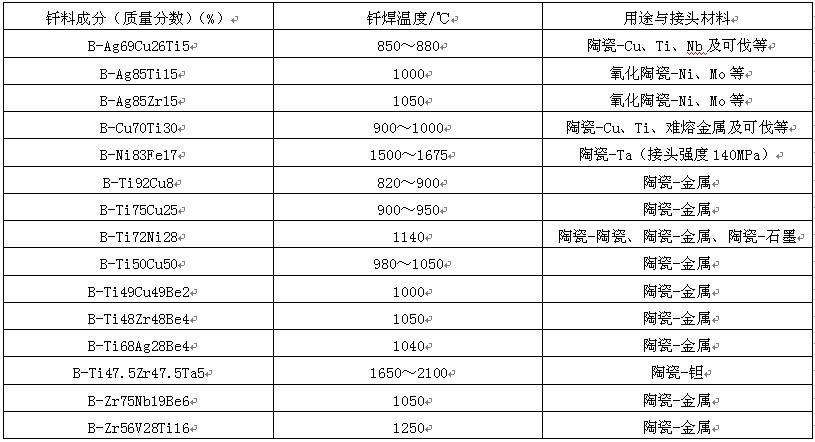

Rau cov brazing ncaj qha ntawm ceramics thiab hlau, brazing muab tub lim hlau uas muaj cov khoom nquag Ti thiab Zr yuav tsum raug xaiv. Cov binary muab tub lim hlau feem ntau yog Ti Cu thiab Ti Ni, uas tuaj yeem siv tau ntawm 1100 ℃. Ntawm cov ternary solder, Ag Cu Ti (W) (TI) yog feem ntau siv solder, uas tuaj yeem siv ncaj qha brazing ntawm ntau yam ceramics thiab hlau. Lub ternary muab tub lim hlau tuaj yeem siv los ntawm cov ntawv ci, hmoov lossis Ag Cu eutectic muab tub lim hlau nrog Ti hmoov. B-ti49be2 brazing muab tub lim hlau muaj qhov zoo sib xws corrosion tsis kam rau cov hlau tsis muaj zog thiab tsis muaj vapor siab. Nws tuaj yeem raug xaiv tshwj xeeb hauv lub tshuab nqus tsev sealing cov pob qij txha nrog oxidation thiab to resistance. Nyob rau hauv ti-v-cr solder, lub melting kub yog qhov qis tshaj (1620 ℃) thaum w (V) yog 30%, thiab qhov sib ntxiv ntawm Cr tuaj yeem txo qhov kub ntawm melting ntau yam. B-ti47.5ta5 solder tsis muaj Cr tau siv ncaj qha brazing ntawm alumina thiab magnesium oxide, thiab nws cov kev sib koom ua haujlwm tuaj yeem ua haujlwm ntawm qhov kub thiab txias ntawm 1000 ℃. Table 14 qhia txog cov dej ntws ncaj qha rau kev sib txuas ntawm cov ceramic thiab hlau.

Table 14 active brazing muab tub lim rau ceramic thiab hlau brazing

2. Brazing tshuab

Pre metallized ceramics tuaj yeem ua rau hauv high-purity inert gas, hydrogen lossis lub tshuab nqus tsev. Nqus brazing feem ntau yog siv rau ncaj qha brazing ntawm ceramics yam tsis muaj metallization.

(1) Universal brazing txheej txheem universal brazing txheej txheem ntawm tej hub thiab hlau yuav muab faib ua xya txheej txheem: nto tu, muab tshuaj txhuam txheej, ceramic nto metallization, npib tsib xee plating, brazing thiab tom qab weld soj ntsuam.

Lub hom phiaj ntawm kev ntxuav saum npoo yog tshem tawm cov roj stain, hws stain thiab oxide zaj duab xis ntawm lub hauv paus hlau. Cov hlau thiab cov hlau yuav tsum tau degreased ua ntej, ces cov oxide zaj duab xis yuav tsum tau muab tshem tawm los ntawm acid los yog alkali ntxuav, ntxuav nrog dej ntws thiab qhuav. Cov khoom uas xav tau siab yuav tsum tau kho cua sov hauv lub tshuab nqus tsev lossis lub qhov cub hydrogen (Ion bombardment method kuj siv tau) ntawm qhov tsim nyog kub thiab sij hawm los ntxuav qhov chaw ntawm qhov chaw. Cov khoom uas huv si yuav tsum tsis txhob kov cov khoom uas muaj roj los yog txhais tes liab qab. Lawv yuav tsum tau muab tso rau hauv cov txheej txheem tom ntej los yog mus rau hauv lub tshuab ziab khaub ncaws. Lawv yuav tsum tsis txhob raug huab cua ntev. Ceramic qhov chaw yuav tsum tau ntxuav nrog acetone thiab ultrasonic, ntxuav nrog dej ntws, thiab thaum kawg boiled ob zaug nrog deionized dej rau 15min txhua zaus.

Paste txheej yog txheej txheem tseem ceeb ntawm ceramic metallization. Thaum lub sij hawm txheej, nws yog siv rau lub ceramic nto yuav metallized nrog ib tug txhuam los yog paste txheej tshuab. Cov txheej thickness feem ntau yog 30 ~ 60mm. Cov tshuaj txhuam hniav feem ntau yog npaj los ntawm cov hmoov hlau ntshiab (qee zaum tsim nyog hlau oxide ntxiv) nrog ib qho me me ntawm li 1 ~ 5um thiab cov nplaum organic.

Cov khoom siv ceramic pasted raug xa mus rau lub qhov cub hydrogen thiab sintered nrog ntub hydrogen los yog tawg ammonia ntawm 1300 ~ 1500 ℃ rau 30 ~ 60min. Rau cov khoom ceramic coated nrog hydrides, lawv yuav tsum tau rhuab mus txog 900 ℃ kom decompose cov hydrides thiab react nrog ntshiab hlau los yog titanium (los yog zirconium) nyob rau hauv ceramic nto kom tau ib tug hlau txheej ntawm ceramic nto.

Rau cov txheej txheem Mo Mn metallized, txhawm rau ua kom ntub dej nrog cov nplaum, ib txheej npib tsib xee ntawm 1.4 ~ 5um yuav tsum tau electroplated los yog coated nrog ib txheej ntawm npib tsib xee hmoov. Yog hais tias lub brazing kub qis dua 1000 ℃, cov nickel txheej yuav tsum tau pre-sintered nyob rau hauv ib tug hydrogen rauv. sintering kub thiab lub sij hawm yog 1000 ℃ / 15 ~ 20min.

Cov khoom siv kho mob yog cov hlau, uas yuav tsum tau sib sau ua ke nrog cov hlau tsis muaj steel lossis graphite thiab ceramics. solder yuav tsum tau ntsia rau ntawm cov pob qij txha, thiab cov workpiece yuav tsum huv si thoob plaws hauv lub lag luam, thiab yuav tsum tsis txhob kov los ntawm txhais tes.

Brazing yuav tsum tau nqa tawm hauv argon, hydrogen lossis lub tshuab nqus tsev. Lub brazing kub nyob ntawm lub brazing muab tub lim hlau. Txhawm rau tiv thaiv kev tawg ntawm cov khoom siv ceramic, qhov cua txias yuav tsum tsis txhob nrawm dhau. Tsis tas li ntawd, brazing kuj tuaj yeem siv qee qhov siab (li 0.49 ~ 0.98mpa).

Ntxiv nrog rau kev tshuaj xyuas qhov zoo ntawm qhov chaw, lub brazed weldments tseem yuav raug thermal shock thiab mechanical khoom tshuaj xyuas. Lub sealing qhov chaw rau cov khoom siv nqus tsev vacuum yuav tsum raug kuaj xyuas raws li cov kev cai cuam tshuam.

(2) Lub brazing ncaj qha thaum brazing ncaj qha (txhim kho hlau txoj kev), ua ntej ntxuav lub nto ntawm ceramic thiab hlau weldments, thiab ces sib sau ua ke. Txhawm rau kom tsis txhob muaj kab nrib pleb tshwm sim los ntawm qhov sib txawv thermal expansion coefficients ntawm cov khoom siv, cov txheej tsis (ib lossis ntau txheej ntawm cov ntawv hlau) tuaj yeem tig ntawm cov khoom siv. Lub brazing muab tub lim hlau yuav tsum tau clamped ntawm ob weldments los yog muab tso rau ntawm qhov chaw uas qhov sib txawv yog sau nrog brazing muab tub lim kom deb li deb tau, thiab ces brazing yuav tsum tau nqa tawm zoo li lub tshuab nqus tsev brazing.

Yog tias Ag Cu Ti solder siv rau kev sib txuas ncaj qha, lub tshuab nqus tsev yuav tsum tau txais kev pom zoo. Thaum lub tshuab nqus tsev kawm ntawv nyob rau hauv lub cub tawg mus txog 2.7 × Pib cua sov ntawm 10-3pa, thiab qhov kub thiab txias tuaj yeem nce sai heev rau lub sijhawm no; Thaum qhov kub thiab txias yog ze rau lub melting point ntawm lub solder, qhov kub thiab txias yuav tsum tau tsa maj mam ua kom qhov kub thiab txias ntawm tag nrho cov seem ntawm cov vuam yuav zoo ib yam; Thaum lub solder yog melted, qhov kub thiab txias yuav tsum tau nce mus rau lub brazing kub, thiab lub sij hawm tuav yuav tsum yog 3 ~ 5min; Thaum lub caij txias, nws yuav tsum tau txias maj mam ua ntej 700 ℃, thiab nws tuaj yeem ua kom txias nrog lub qhov cub tom qab 700 ℃.

Thaum Ti Cu active solder yog ncaj qha brazed, daim ntawv ntawm solder yuav ua tau Cu ntawv ci ntxiv rau Ti hmoov los yog Cu qhov chaw ntxiv rau Ti ntawv ci, los yog cov ceramic nto tuaj yeem coated nrog Ti hmoov ntxiv rau Cu ntawv ci. Ua ntej brazing, tag nrho cov hlau yuav tsum tau degassed los ntawm lub tshuab nqus tsev. Lub degassing kub ntawm oxygen dawb tooj liab yuav tsum yog 750 ~ 800 ℃, thiab Ti, Nb, Ta, thiab lwm yam yuav tsum degassed ntawm 900 ℃ rau 15min. Lub sijhawm no, lub tshuab nqus tsev kawm ntawv yuav tsum tsis pub tsawg dua 6.7 × 10-3Pa. Thaum lub sij hawm brazing, sib sau cov khoom siv rau hauv cov khoom siv, ua kom sov rau hauv lub tshuab nqus tsev rau 900 ~ 1120 ℃, thiab lub sijhawm tuav yog 2 ~ 5min. Thaum lub sij hawm tag nrho cov txheej txheem brazing, lub tshuab nqus tsev kawm ntawv yuav tsum tsis pub tsawg tshaj 6.7 × 10-3Pa.

Cov txheej txheem brazing ntawm Ti Ni txoj kev zoo ib yam li Ti Cu txoj kev, thiab lub brazing kub yog 900 ± 10 ℃.

(3) Oxide brazing method oxide brazing method yog ib txoj hauv kev kom paub txog kev sib txuas txhim khu kev qha los ntawm kev siv iav theem tsim los ntawm melting ntawm oxide solder kom nkag mus rau hauv ceramics thiab ntub cov hlau nto. Nws tuaj yeem txuas ceramics nrog ceramics thiab ceramics nrog hlau. Oxide brazing muab tub lim hlau yog tsim los ntawm Al2O3, Cao, Bao thiab MgO. Los ntawm kev ntxiv B2O3, Y2O3 thiab ta2o3, brazing muab tub lim hlau nrog ntau cov ntsiab lus melting thiab linear expansion coefficients tau. Tsis tas li ntawd, fluoride brazing muab tub lim hlau nrog CaF2 thiab NaF raws li cov khoom tseem ceeb kuj tuaj yeem siv los txuas cov ceramics thiab hlau kom tau txais cov pob qij txha uas muaj zog thiab kub ua hauj.

Post lub sij hawm: Jun-13-2022