1. Solder

Txhua hom solders nrog kub qis dua 3000 ℃ tuaj yeem siv rau W brazing, thiab tooj liab lossis nyiaj raws li cov khoom siv tuaj yeem siv rau cov khoom uas kub qis dua 400 ℃;Kub raws, manganese raws, manganese raws, palladium raws lossis laum raws li cov khoom siv hlau feem ntau yog siv rau cov khoom siv ntawm 400 ℃ thiab 900 ℃;Rau cov khoom siv siab tshaj 1000 ℃, cov hlau ntshiab xws li Nb, Ta, Ni, Pt, PD thiab Mo feem ntau yog siv.Kev ua hauj lwm kub ntawm cov khoom siv brazed nrog platinum puag solder tau mus txog 2150 ℃.Yog hais tias 1080 ℃ diffusion kev kho yog nqa tawm tom qab brazing, qhov siab tshaj plaws ua hauj lwm kub yuav ncav cuag 3038 ℃.

Feem ntau ntawm cov solders siv rau brazing w yuav siv tau rau brazing Mo, thiab tooj liab los yog nyiaj raws li solders yuav siv tau rau Mo Cheebtsam ua hauj lwm hauv qab no 400 ℃;Rau cov khoom siv hluav taws xob thiab cov khoom siv tsis yog cov qauv ua haujlwm ntawm 400 ~ 650 ℃, Cu Ag, Au Ni, PD Ni los yog Cu Ni solders tuaj yeem siv tau;Titanium raws li los yog lwm yam ntshiab hlau muab tub lim hlau nrog cov ntsiab lus melting siab tuaj yeem siv rau cov khoom ua haujlwm ntawm qhov kub siab dua.Nws yuav tsum tau muab sau tseg tias manganese raws li, cobalt raws li thiab nickel raws li muab tub lim hlau feem ntau tsis pom zoo kom tsis txhob tsim cov nkig intermetallic tebchaw nyob rau hauv lub brazing pob qij txha.

Thaum TA lossis Nb cov khoom siv qis dua 1000 ℃, tooj liab raws li manganese raws, cobalt raws li, titanium raws li, npib tsib xee raws, kub raws li thiab palladium raws li txhaj tshuaj tuaj yeem xaiv, suav nrog Cu Au, Au Ni, PD Ni thiab Pt Au_ Ni thiab Cu Sn solders muaj wettability zoo rau TA thiab Nb, zoo brazing seam tsim thiab siab sib koom ua ke.Raws li nyiaj raws li cov khoom siv hlau zoo li ua rau cov hlau brazing nkig, lawv yuav tsum raug zam kom ntau li ntau tau.Rau cov khoom siv nyob nruab nrab ntawm 1000 ℃ thiab 1300 ℃, cov hlau ntshiab Ti, V, Zr lossis alloys raws li cov hlau uas tsim cov khoom tsis kawg thiab ua kua nrog lawv yuav tsum raug xaiv ua cov khoom siv hlau brazing.Thaum qhov kev pabcuam kub siab dua, cov hlau muab tub lim uas muaj HF tuaj yeem xaiv tau.

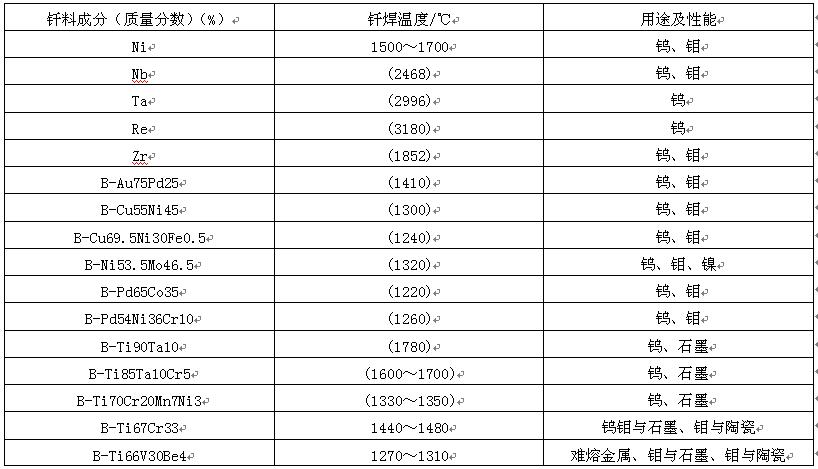

W. Saib cov lus 13 rau brazing muab tub lim rau Mo, Ta thiab Nb ntawm qhov kub thiab txias.

Table 13 brazing muab tub lim hlau rau kub kub brazing ntawm refractory hlau

Ua ntej brazing, nws yuav tsum tau ua tib zoo tshem tawm cov oxide nyob rau saum npoo ntawm cov hlau refractory.Kev sib tsoo tshuab, xuab zeb blasting, ultrasonic tu lossis tshuaj ntxuav yuav siv tau.Brazing yuav tsum tau nqa tawm tam sim tom qab kev ntxuav.

Vim yog lub hauv paus brittleness ntawm W, w qhov yuav tsum tau ua tib zoo saib xyuas hauv kev ua haujlwm sib dhos kom tsis txhob tawg.Txhawm rau tiv thaiv kev tsim ntawm brittle tungsten carbide, kev sib cuag ncaj qha ntawm W thiab graphite yuav tsum raug zam.Prestressing vim ua ntej vuam los yog vuam yuav tsum raug tshem tawm ua ntej vuam.W yog qhov yooj yim rau oxidize thaum kub nce.Lub tshuab nqus tsev kawm ntawv yuav tsum siab txaus thaum brazing.Thaum brazing tau ua nyob rau hauv qhov kub ntawm 1000 ~ 1400 ℃, lub tshuab nqus tsev kawm ntawv yuav tsum tsis pub tsawg tshaj 8 × 10-3Pa. qhov kev kho diffusion tom qab vuam.Piv txwv li, b-ni68cr20si10fel solder yog siv rau braze W ntawm 1180 ℃.Tom qab peb qhov kev kho mob diffusion ntawm 1070 ℃ / 4h, 1200 ℃ / 3.5h thiab 1300 ℃ / 2h tom qab vuam, qhov kev pabcuam kub ntawm cov sib koom ua ke tuaj yeem ncav cuag ntau dua 2200 ℃.

Qhov me me coefficient ntawm thermal expansion yuav tsum raug coj mus rau hauv tus account thaum sib dhos lub brazed sib koom ntawm Mo, thiab qhov sib txuas sib txuas yuav tsum nyob rau hauv thaj tsam ntawm 0.05 ~ 0.13MM.Yog tias siv cov khoom siv, xaiv cov khoom siv nrog me me coefficient ntawm thermal expansion.Mo recrystallization tshwm sim thaum nplaim taws brazing, tswj cua sov cua sov, lub tshuab nqus tsev vacuum, induction rauv thiab cov cua kub tsis kam tshaj qhov kub ntawm recrystallization los yog qhov kub ntawm recrystallization txo vim qhov diffusion ntawm solder ntsiab.Yog li ntawd, thaum lub brazing kub nyob ze rau lub recrystallization kub, lub sij hawm luv luv lub brazing, qhov zoo dua.Thaum brazing saum toj no lub recrystallization kub ntawm Mo, lub sij hawm brazing thiab txias npaum li cas yuav tsum tau tswj kom tsis txhob tawg los ntawm ceev heev txias.Thaum siv cov oxyacetylene nplaim taws, nws yog qhov zoo tshaj plaws los siv cov flux sib xyaw, uas yog, muaj borate lossis silver brazing flux ntxiv rau cov dej kub kub uas muaj calcium fluoride, uas tuaj yeem tau txais kev tiv thaiv zoo.Txoj kev yog thawj lub tsho tiv no ntawm cov nyiaj brazing flux nyob rau saum npoo ntawm Mo, thiab tom qab ntawd coated high-temperature flux.Cov nyiaj brazing flux muaj kev ua haujlwm nyob rau hauv qhov kub thiab txias, thiab qhov kub ntawm qhov kub thiab txias tuaj yeem ncav cuag 1427 ℃.

TA los yog Nb Cheebtsam yog zoo dua brazed nyob rau hauv lub nqus tsev vacuum, thiab lub nqus tsev kawm ntawv yog tsis tsawg tshaj li 1.33 × 10-2Pa.Yog hais tias brazing yog ua raws li kev tiv thaiv ntawm inert gas, roj impurities xws li carbon monoxide, ammonia, nitrogen thiab carbon dioxide yuav tsum tau nruj me ntsis tshem tawm.Thaum brazing los yog tiv thaiv brazing yog nqa tawm hauv huab cua, tshwj xeeb brazing muab tub lim hlau thiab flux tsim nyog yuav tsum tau siv.Txhawm rau tiv thaiv TA lossis Nb los ntawm kev sib cuag nrog cov pa oxygen ntawm qhov kub thiab txias, txheej ntawm cov xim hlau tooj liab lossis npib tsib xee tuaj yeem plated rau saum npoo thiab sib haum diffusion annealing kev kho mob tuaj yeem nqa tawm.

Post lub sij hawm: Jun-13-2022