Brazing ntawm Superalloys

(1) Brazing yam ntxwv superalloys tuaj yeem muab faib ua peb pawg: npib tsib xee puag, hlau puag thiab cobalt puag. Lawv muaj cov khoom siv zoo, oxidation tsis kam thiab corrosion kuj ntawm qhov kub thiab txias. Nickel puag alloy yog siv dav hauv kev tsim khoom.

Lub superalloy muaj ntau Cr, thiab Cr2O3 oxide zaj duab xis uas nyuaj rau tshem tawm yog tsim rau saum npoo thaum cua sov. Nickel puag superalloys muaj Al thiab Ti, uas yooj yim rau oxidize thaum rhuab. Yog li ntawd, txhawm rau tiv thaiv lossis txo cov oxidation ntawm superalloys thaum cua sov thiab tshem tawm cov oxide zaj duab xis yog qhov teeb meem tseem ceeb thaum lub sij hawm brazing. Raws li borax los yog boric acid nyob rau hauv lub flux tuaj yeem ua rau corrosion ntawm lub hauv paus hlau ntawm qhov kub thiab txias, boron precipitated tom qab cov tshuaj tiv thaiv tuaj yeem nkag mus rau hauv lub hauv paus hlau, ua rau muaj kev cuam tshuam ntawm intergranular. Rau cam khwb cia npib tsib xee puag alloys nrog siab Al thiab Ti txheem, lub tshuab nqus tsev kawm ntawv hauv lub xeev kub yuav tsum tsis txhob tsawg tshaj li 10-2 ~ 10-3pa thaum lub sij hawm brazing kom tsis txhob oxidation ntawm lub alloy nto thaum cua sov.

Rau kev daws kom muaj zog thiab nag lossis daus ntxiv dag zog rau npib tsib xee hauv paus alloys, lub brazing kub yuav tsum tau ua raws li cov cua kub ntawm cov kev kho mob los xyuas kom meej tag nrho cov dissolution ntawm alloy ntsiab. Lub brazing kub yog tsawg heev, thiab cov ntsiab lus alloy tsis tuaj yeem yaj tag; Yog hais tias lub brazing kub siab dhau lawm, lub hauv paus hlau nplej yuav loj hlob tuaj, thiab cov khoom siv yuav tsis rov qab los txawm tias tom qab kev kho cua sov. Cov khoom kub ntawm cov cam khwb cia hlau alloys yog siab, uas feem ntau yuav tsis cuam tshuam rau cov khoom siv vim yog kub brazing kub.

Qee cov nickel puag superalloys, tshwj xeeb tshaj yog nag lossis daus muaj zog alloys, muaj kev ntxhov siab tawg. Ua ntej brazing, qhov kev ntxhov siab tsim nyob rau hauv cov txheej txheem yuav tsum tau muab tshem tawm tag nrho, thiab cov thermal stress yuav tsum tau txo qis thaum lub sij hawm brazing.

(2) Cov khoom siv tooj liab npib tsib xee alloy tuaj yeem ua nrog cov nyiaj hauv paus, tooj liab ntshiab, npib tsib xee puag thiab cov khoom siv. Thaum qhov kub thiab txias ntawm kev sib koom ua haujlwm tsis siab, cov khoom siv nyiaj siv tau tuaj yeem siv tau. Muaj ntau ntau hom nyiaj raws li solders. Txhawm rau txo qhov kev ntxhov siab sab hauv thaum lub sij hawm brazing cua sov, nws yog qhov zoo tshaj plaws los xaiv cov solder uas tsis tshua muaj melting kub. Fb101 flux tuaj yeem siv rau brazing nrog nyiaj puag muab tub lim hlau. Fb102 flux yog siv rau brazing nag lossis daus ntxiv dag zog superalloy nrog cov ntsiab lus txhuas siab tshaj plaws, thiab 10% ~ 20% sodium silicate lossis aluminium flux (xws li fb201) ntxiv. Thaum lub brazing kub tshaj 900 ℃, fb105 flux yuav tsum tau xaiv.

Thaum brazing nyob rau hauv lub tshuab nqus tsev los yog kev tiv thaiv huab cua, ntshiab tooj liab yuav siv tau raws li brazing muab tub lim hlau. Lub brazing kub yog 1100 ~ 1150 ℃, thiab qhov sib koom ua ke yuav tsis tsim kev ntxhov siab tawg, tab sis qhov kub ua haujlwm yuav tsum tsis pub tshaj 400 ℃.

Nickel puag brazing muab tub lim hlau yog feem ntau siv brazing muab tub lim hlau hauv Superalloys vim nws qhov kub siab ua haujlwm zoo thiab tsis muaj kev ntxhov siab tawg thaum lub sij hawm brazing. Lub ntsiab alloy ntsiab nyob rau hauv npib tsib xee puag solder yog Cr, Si, B, thiab ib tug me me ntawm solder kuj muaj Fe, W, thiab lwm yam. Piv nrog rau ni-cr-si-b, b-ni68crwb brazing muab tub lim hlau yuav txo tau cov intergranular infiltration B rau hauv lub hauv paus hlau thiab nce lub melting kub lub caij. Nws yog brazing muab tub lim hlau rau brazing high-temperature ua hauj lwm qhov chaw thiab turbine hniav. Txawm li cas los xij, qhov fluidity ntawm W-muaj solder ua phem dua thiab qhov sib koom ua ke tsis yooj yim los tswj.

Lub active diffusion brazing muab tub lim hlau tsis muaj Si keeb thiab muaj oxidation zoo heev thiab vulcanization kuj. Lub brazing kub tuaj yeem xaiv los ntawm 1150 ℃ mus rau 1218 ℃ raws li hom solder. Tom qab brazing, lub brazed sib koom nrog tib yam khoom raws li lub hauv paus hlau tuaj yeem tau tom qab 1066 ℃ diffusion kho.

(3) Brazing txheej txheem npib tsib xee alloy tuaj yeem txais cov brazing hauv kev tiv thaiv cua sov, lub tshuab nqus tsev brazing thiab kev sib txuas ua kua theem. Ua ntej brazing, qhov saum npoo yuav tsum tau degreased thiab oxide tshem tawm los ntawm cov ntawv xuab zeb polishing, muaj lub log polishing, acetone txhuam thiab tshuaj ntxuav. Thaum xaiv cov txheej txheem brazing, nws yuav tsum tau muab sau tseg tias cov cua kub yuav tsum tsis txhob siab dhau thiab lub sij hawm brazing yuav tsum luv kom tsis txhob muaj zog tshuaj tiv thaiv ntawm flux thiab lub hauv paus hlau. Txhawm rau tiv thaiv lub hauv paus hlau los ntawm kev tawg, cov txheej txheem txias txias yuav tsum tau ua kom muaj kev ntxhov siab ua ntej vuam, thiab vuam cua sov yuav tsum zoo ib yam li qhov ua tau. Rau nag lossis daus muaj zog superalloys, cov khoom yuav tsum raug kho kom zoo ua ntej, tom qab ntawd brazed ntawm qhov kub thiab txias me ntsis tshaj qhov kev laus txhawb kev kho mob, thiab thaum kawg kev laus kho.

1) Brazing nyob rau hauv kev tiv thaiv cua sov cua sov brazing nyob rau hauv tiv thaiv cua sov yuav tsum tau siab purity ntawm shielding roj. Rau superalloys nrog w (AL) thiab w (TI) tsawg dua 0.5%, qhov dej lwg taw tes yuav tsum qis dua -54 ℃ thaum siv hydrogen lossis argon. Thaum cov ntsiab lus ntawm Al thiab Ti nce, lub alloy nto tseem oxidizes thaum rhuab. Cov kev ntsuas hauv qab no yuav tsum tau ua; Ntxiv me me ntawm flux (xws li fb105) thiab tshem tawm cov oxide zaj duab xis nrog flux; 0.025 ~ 0.038mm tuab txheej yog plated rau ntawm qhov chaw; Txau lub solder rau saum npoo ntawm cov khoom yuav tsum tau brazed ua ntej; Ntxiv me me ntawm cov pa roj, xws li boron trifluoride.

2) Lub tshuab nqus tsev vacuum brazing yog dav siv kom tau txais kev tiv thaiv zoo dua thiab kev ua haujlwm zoo. Saib cov lus 15 rau cov khoom siv ntawm cov nickel puag superalloy pob qij txha. Rau superalloys nrog w (AL) thiab w (TI) tsawg dua 4%, nws yog qhov zoo dua rau electroplate ib txheej ntawm 0.01 ~ 0.015mm npib tsib xee rau ntawm qhov chaw, txawm hais tias cov wetting ntawm solder tuaj yeem ua kom tsis muaj kev kho tshwj xeeb. Thaum w (AL) thiab w (TI) ntau tshaj 4%, lub thickness ntawm nickel txheej yuav tsum yog 0.020.03mm. Cov txheej txheej dhau lawm tsis muaj kev tiv thaiv, thiab cov txheej tuab heev yuav txo tau lub zog ntawm kev sib koom tes. Cov khoom yuav tsum tau welded tseem tuaj yeem muab tso rau hauv lub thawv rau lub tshuab nqus tsev vacuum. Lub thawv yuav tsum tau ntim nrog getter. Piv txwv li, Zr absorbs roj ntawm qhov kub thiab txias, uas tuaj yeem tsim lub tshuab nqus tsev hauv zos hauv lub thawv, yog li tiv thaiv oxidation ntawm alloy nto.

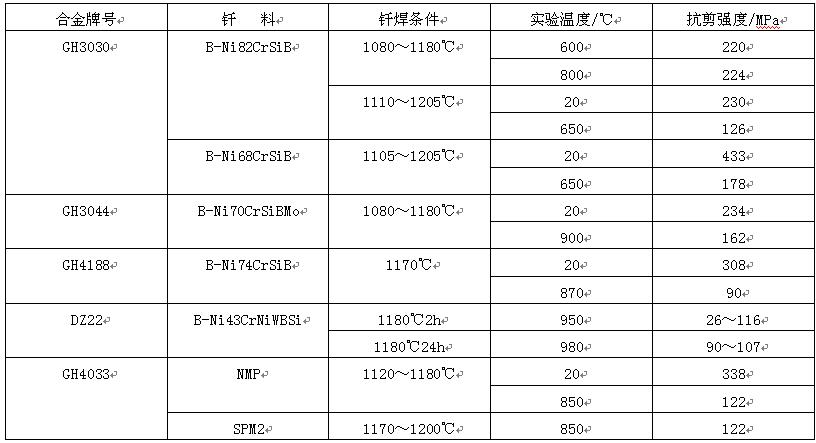

Table 15 txhua yam khoom ntawm Nqus Brazed Joints ntawm raug nickel puag superalloys

Lub microstructure thiab lub zog ntawm brazed sib koom ntawm Superalloy hloov nrog qhov sib txawv ntawm brazing, thiab kev kho diffusion tom qab brazing yuav ntxiv qhov siab tshaj plaws ntawm qhov sib txawv ntawm qhov sib koom ua ke. Noj Inconel alloy ua piv txwv, qhov sib txawv siab tshaj plaws ntawm Inconel sib koom ua ke nrog b-ni82crsib tuaj yeem ncav cuag 90um tom qab diffusion kho ntawm 1000 ℃ rau 1H; Txawm li cas los xij, rau cov pob qij txha brazed nrog b-ni71crsib, qhov sib txawv siab tshaj plaws yog li 50um tom qab diffusion kho ntawm 1000 ℃ rau 1H.

3) Transient kua theem kev twb kev txuas transient kua theem kev twb kev txuas siv cov interlayer alloy (kwv yees 2.5 ~ 100um tuab) uas nws melting point yog qis dua lub hauv paus hlau raws li cov muab tub lim hlau. Nyob rau hauv ib tug me me siab (0 ~ 0.007mpa) thiab qhov tsim nyog kub (1100 ~ 1250 ℃), cov khoom interlayer thawj melts thiab moistens lub hauv paus hlau. Vim yog qhov nrawm nrawm ntawm cov ntsiab lus, isothermal solidification tshwm sim ntawm kev sib koom ua ke los tsim cov kev sib koom ua ke. Txoj kev no zoo heev txo qhov kev sib txuam ntawm cov hlau hauv qab thiab txo qhov vuam siab. Lub ntsiab tsis sib xws ntawm cov kua theem txuas yog siab, kub, tuav lub sij hawm thiab muaj pes tsawg leeg ntawm interlayer. Siv lub zog tsawg dua kom cov mating nto ntawm cov welment nyob rau hauv kev sib cuag zoo. Cov cua kub kub thiab lub sijhawm muaj kev cuam tshuam zoo rau kev ua haujlwm ntawm kev sib koom ua ke. Yog tias qhov sib koom ua ke yuav tsum muaj zog npaum li lub hauv paus hlau thiab tsis cuam tshuam rau kev ua haujlwm ntawm lub hauv paus hlau, cov txheej txheem kev sib txuas ntawm qhov kub siab (xws li ≥ 1150 ℃) thiab lub sijhawm ntev (xws li 8 ~ 24h) yuav tsum tau saws; Yog tias qhov kev sib txuas zoo ntawm kev sib koom ua ke raug txo los yog cov hlau hauv paus tsis tuaj yeem tiv taus qhov kub thiab txias, qhov kub qis (1100 ~ 1150 ℃) thiab lub sijhawm luv (1 ~ 8h) yuav tsum tau siv. Cov txheej txheem nruab nrab yuav tsum siv cov txheej txheem sib txuas ntawm cov hlau sib txuas ua cov ntsiab lus sib txawv, thiab ntxiv cov khoom cua txias sib txawv, xws li B, Si, Mn, Nb, thiab lwm yam. Piv txwv li, cov khoom sib xyaw ntawm Udimet alloy yog ni-15cr-18.5co-4.3al-3.3ti-5mo, thiab cov txheej txheem nruab nrab ntawm cov txheej txheem nruab nrab rau kev sib txuas ua kua theem yog 55cr-18.5co. Tag nrho cov ntsiab lus no tuaj yeem txo qhov kub ntawm Ni Cr lossis Ni Cr Co alloys kom qis tshaj, tab sis cov nyhuv ntawm B yog qhov pom tseeb tshaj plaws. Tsis tas li ntawd, qhov siab diffusion ntawm B tuaj yeem ua homogenize interlayer alloy thiab lub hauv paus hlau.

Post lub sij hawm: Jun-13-2022