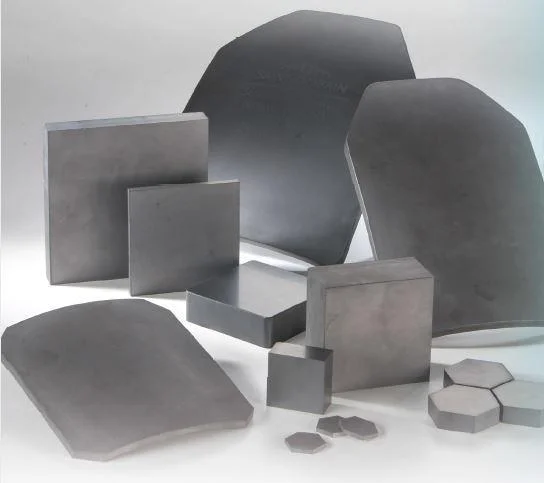

Silicon carbide ceramics muaj qhov kub thiab txias zog, kub oxidation tsis kam, hnav tsis kam, zoo thermal stability, me me coefficient ntawm thermal expansion, siab thermal conductivity, siab hardness, kub poob tsis kam, tshuaj corrosion kuj thiab lwm yam zoo heev zog. Nws tau dav siv nyob rau hauv tsheb, mechanization, ib puag ncig tiv thaiv, aerospace technology, cov ntaub ntawv electronics, lub zog thiab lwm yam teb, thiab tau dhau los ua ib tug irreplaceable structural ceramic nrog zoo heev kev ua tau zoo nyob rau hauv ntau yam industrial teb. Tam sim no cia kuv qhia koj!

Pressureless sintering

Pressureless sintering yog suav tias yog txoj kev pheej hmoo tshaj plaws rau SiC sintering. Raws li kev sib txawv sintering mechanisms, pressureless sintering tuaj yeem muab faib ua cov khoom-theem sintering thiab kua-theem sintering. Los ntawm ultra-fine β- Tus nqi tsim nyog ntawm B thiab C (cov ntsiab lus oxygen tsawg dua 2%) tau ntxiv rau SiC hmoov tib lub sijhawm, thiab s. proehazka tau sintered rau SiC sintered lub cev nrog ceev siab tshaj 98% ntawm 2020 ℃. A. Mulla et al. Al2O3 thiab Y2O3 tau siv los ua additives thiab sintered ntawm 1850-1950 ℃ rau 0.5 μ m β- SiC (particle nto muaj me me ntawm SiO2). Cov txheeb ze ntom ntom ntawm SiC ceramics tau ntau dua 95% ntawm qhov kev xav tau, thiab cov nplej loj me me thiab qhov nruab nrab loj. Nws yog 1.5 microns.

Kub xovxwm sintering

Ntshiab SiC tuaj yeem tsuas yog sintered compactly ntawm qhov kub siab heev yam tsis muaj sintering additives, yog li ntau tus neeg siv cov txheej txheem kub sintering rau SiC. Muaj ntau cov lus ceeb toom txog qhov kub nias sintering ntawm SiC los ntawm kev ntxiv sintering pab. Alliegro et al. Kawm txog cov nyhuv ntawm boron, txhuas, npib tsib xee, hlau, chromium thiab lwm yam hlau additives ntawm SiC densification. Cov txiaj ntsig tau pom tias txhuas thiab hlau yog cov khoom siv zoo tshaj plaws los txhawb SiC kub nias sintering. FFlange tau kawm txog qhov sib txawv ntawm qhov sib txawv ntawm Al2O3 ntawm cov khoom ntawm kub nias SiC. Nws raug suav hais tias qhov ntom ntom ntawm kub nias SiC cuam tshuam nrog lub tshuab ntawm kev sib cais thiab nag lossis daus. Txawm li cas los xij, cov txheej txheem kub xovxwm sintering tsuas tuaj yeem tsim SiC qhov chaw nrog cov duab yooj yim. Qhov ntau ntawm cov khoom tsim los ntawm ib-lub sij hawm kub xovxwm sintering txheej txheem yog heev me me, uas yog tsis conducive rau industrial ntau lawm.

Kub isostatic nias sintering

Txhawm rau kov yeej qhov tsis txaus ntawm cov txheej txheem sintering ib txwm, B-hom thiab C-hom tau siv los ua cov khoom siv ntxiv thiab kub isostatic pressing sintering tshuab tau txais yuav. Nyob rau ntawm 1900 ° C, zoo crystalline ceramics nrog ib tug ceev ntau dua 98 tau txais, thiab lub zog dabtsi yog khoov ntawm chav tsev kub yuav ncav cuag 600 MPa. Txawm hais tias kub iSostatic nias Sintering tuaj yeem tsim cov qauv siv hluav taws xob ntau thiab cov sintering yuav tsum tau muab ntim, uas yog qhov nyuaj kom ua tiav kev lag luam.

Cov tshuaj tiv thaiv sintering

Cov tshuaj tiv thaiv sintered silicon carbide, tseem hu ua tus kheej sib koom ua ke silicon carbide, yog hais txog cov txheej txheem uas ntxeem tau ntawm cov pa roj los yog kua theem los txhim kho billet zoo, txo cov porosity, thiab sinter tiav cov khoom nrog qee lub zog thiab qhov tseeb. noj α- SiC hmoov thiab graphite yog tov nyob rau hauv ib qho kev faib ua feem thiab rhuab mus txog 1650 ℃ los ua ib tug square billet. Nyob rau tib lub sijhawm, nws nkag mus lossis nkag mus rau hauv lub billet los ntawm gaseous Si thiab reacts nrog graphite los ua β- SiC, ua ke nrog cov α- SiC uas twb muaj lawm. Thaum Si yog infiltrated tag, cov tshuaj tiv thaiv sintered lub cev nrog tag nrho ntom thiab tsis shrinkage loj tuaj yeem tau. Piv nrog rau lwm cov txheej txheem sintering, qhov hloov pauv loj ntawm cov tshuaj tiv thaiv sintering hauv cov txheej txheem densification yog me me, thiab cov khoom uas muaj qhov loj me tuaj yeem npaj tau. Txawm li cas los xij, qhov muaj ntau ntawm SiC hauv lub cev sintered ua rau cov khoom kub kub ntawm cov tshuaj tiv thaiv sintered SiC ceramics zuj zus.

Post lub sij hawm: Jun-08-2022