Nqus Debinding thiab Sintering rauv (MIM rauv, hmoov metallurgy rauv)

Yam ntxwv

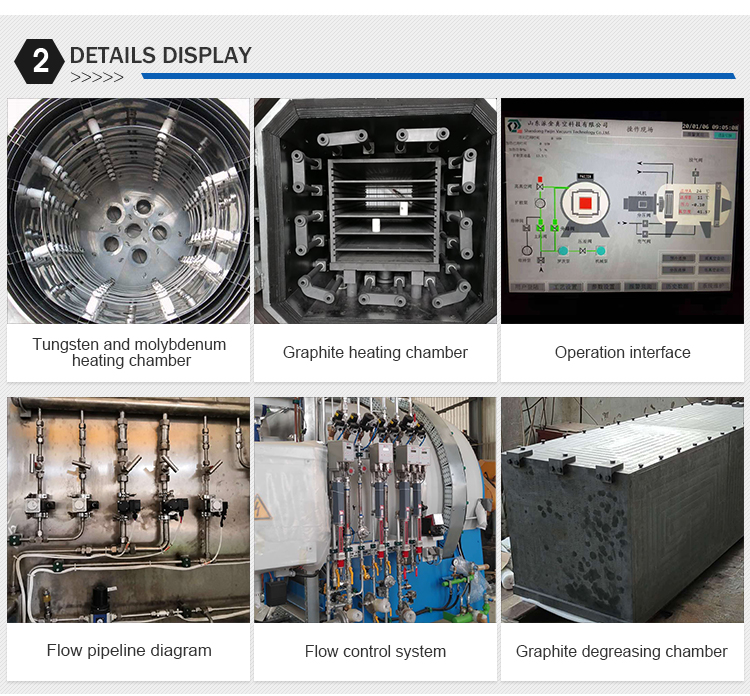

1. Graphite rwb thaiv tsev screen / hlau tshuaj ntsuam yeem, cua sov caij 360 degree puag ncig hluav taws xob cua sov, txhim khu kev qha rwb thaiv tsev tsim.

2. Siab kub uniformity thiab thermal efficiency

3. Lub tshuab nqus tsev ib nrab siab / ntau thaj chaw kub tswj kev ua haujlwm.

4. Cov khoom siv tsis siv neeg puv, kev nyab xeeb zoo meej thiab lub tswb tsis zoo.

5. Kev tswj cov txheej txheem kom ua tiav qhov zoo ib yam thiab tiv thaiv kev ua qias tuaj ntawm qhov chaw thiab qhov chaw kub.

6. Nrog kaw lub thawv degreasing thiab lub tshuab nqus tsev condenser kom txo cov pa phem ntawm cov cua sov chamber thiab chav tsev.

7. Tiv thaiv kom txhob muaj kuab paug rau cov khoom hauv lub qhov cub. Lub thawv square degreasing yog siv los cuam tshuam nrog ntau tus molding additives.

8. Nws muaj cov haujlwm ntawm lub tshuab nqus tsev hloov pauv, lub tshuab nqus tsev sintering, micro-positive siab sintering thiab lwm yam.

9. Qhov tseeb thermal rwb thaiv tsev qauv thiab cov ntaub ntawv yog siv, lub siab tsis kam yog muaj zog, thiab lub zog txuag yog pom tseeb.

10.It muaj cov haujlwm ntawm overtemperature thiab overpressure tswb, txhua yam tsis siv neeg siab tiv thaiv, tsis siv neegoverpressure nyem tiv thaiv, kev cuam tshuam cuam tshuam thiab lwm yam, cov cuab yeej siv siab ruaj ntseg.

11.Remote lag luam, tej thaj chaw deb kuaj mob thiab tej thaj chaw deb software upgrade zog, thiab lwm yam.

Standard qauv specification thiab parameters

| Qauv | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Effective hot zone LWH (mm) | 200 * 200 * 300 hli | 300 * 300 * 600 hli | 300 * 300 * 900 hli | 400 * 400 * 1200 hli | 500 * 500 * 1800 hli |

| Load hnyav (kg) | 100 | 200 | 400 | 600 | 10000 |

| Lub zog cua sov (kw) | 65 | 80 | 150 | 200 | 450 |

| Qhov kub thiab txias (℃) | 1600 | ||||

| Kev tswj qhov kub thiab txias (℃) | ± 1 | ||||

| Lub qhov cub kub uniformity (℃) | ± 3 | ||||

| Lub tshuab nqus tsev degree (Pa) | 4.0 * E -1 | ||||

| Pumping tus nqi (rau 5 pa) | ≤ 10 feeb | ||||

| Siab nce tus nqi (Pa / H) | ≤ 0.5 | ||||

| Debinding tus nqi | ≥ 97.5% | ||||

| Debinding txoj kev | N2 hauv qhov tsis zoo siab, H2 hauv huab cua | ||||

| Cov roj nkag | N2, H2, Ar | ||||

| Txoj kev ua kom txias | inert gas txias | ||||

| Txoj kev sintering | Nqus sintering, ib nrab siab sintering, pressureless sintering | ||||

| Rauv qauv | Kab rov tav, ib chav | ||||

| Rauv qhov rooj qhib txoj kev | Hom pob khawm | ||||

| Cov khoom cua sov | Graphit cua sov ntsiab | ||||

| Cua sov chav | Cov qauv tsim ntawm Graphit nyuaj xav thiab muag muag | ||||

| Thermocouple | C Hom | ||||

| PLC & cov khoom siv hluav taws xob | Siemens | ||||

| Kub tswj | EUROTHERM | ||||

| Lub tshuab nqus tsev twj | Mechanical twj tso kua mis thiab cov hauv paus hniav twj tso kua mis | ||||

| Customized xaiv tau ntau yam | |||||

| Qhov kub siab tshaj plaws | 1300-2800 ℃ | ||||

| Qhov kub siab tshaj plaws degree | 6.7 * E -3 Pa | ||||

| Rauv qauv | Kab rov tav, ntsug, Ib chav | ||||

| Txoj kev qhib qhov rooj | Hom pob khawm, Lifting hom, Flat hom | ||||

| Cov khoom cua sov | Graphit cua sov ntsiab, Mo cua sov ntsiab | ||||

| Cua sov chav | Composed graphit xav, Tag nrho cov hlau reflecting screen | ||||

| Lub tshuab nqus tsev twj | Mechanical twj tso kua mis thiab cov hauv paus hniav twj tso kua mis; Mechanical, Roots thiab diffusion twj | ||||

| PLC & cov khoom siv hluav taws xob | Siemens; Omron; Mitsubishi; Siemens | ||||

| Kub tswj | EUROTHERM;S HIMADEN | ||||